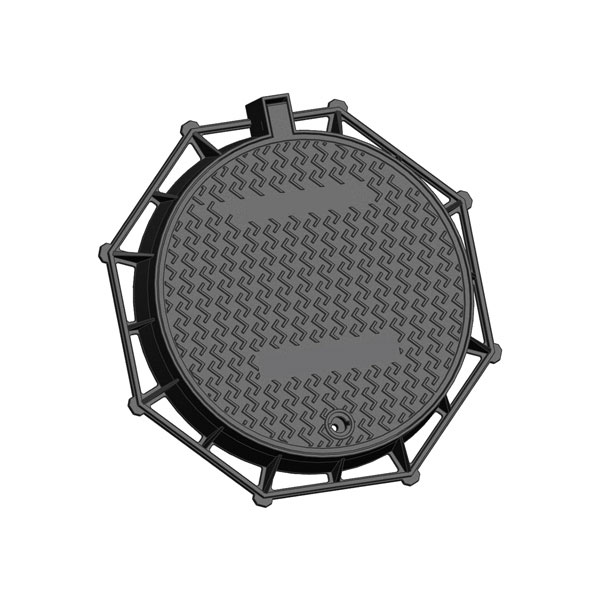

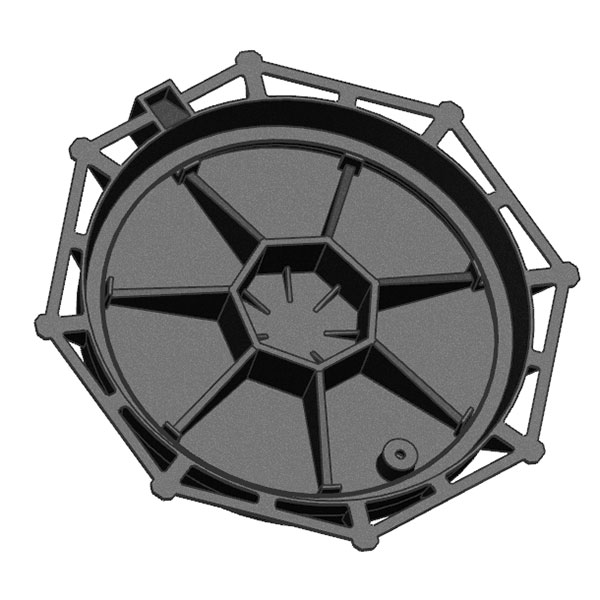

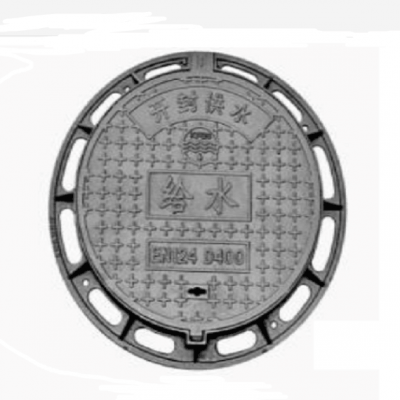

ICMQ Circular Manhole Cover , D400 Manhole Cover Round Eight Angle

Applications:

Ductile iron castings have been used in almost all major industrial sectors, requiring high strength, ductility, toughness, wear resistance, resistance to severe thermal and mechanical shocks, high or low temperatures, corrosion resistance and dimensional stability. In order to meet these variations in the conditions of use, there are many grades of ductile iron available, providing a wide range of mechanical properties and kinematic properties. Most ductile iron castings, as defined by ISO 1083, are mainly produced in non-alloyed state. Obviously, this range includes high-strength grades with tensile strength greater than 800 Newtons/mm and elongation of 2%. QT500-7, a general-purpose material for ductile iron manhole covers, has a Brinell hardness of 170-230HB. The other extreme is a high-resistance grade with an elongation of more than 17% and a correspondingly low strength (minimum of 370 N/mm scoop. Strength and elongation are not the only roots of the designer’s choice of material, while other decisive important properties Also included are yield strength, modulus of elasticity, wear and fatigue strength, hardness and impact properties. In addition, corrosion resistance and oxidation resistance and electromagnetic properties may be critical to the designer. To meet these special uses, a group has been developed. Austenitic ductile iron, usually called Ni-Resis, is a ductile iron. These austenitic ductile irons are mainly alloyed with zinc, chromium and manganese and are listed as international standards.

Competitive Advantage:

A. All kinds of size as customer’s requirements;

B. Small quantity trial order is welcome

C. Customized design is available and free, Such as Color, Logo, Panel, Load and Dimension etc.

D. Quality control and Promptly delivery

E. Good service after sales.